LAMINOWANIE PŁOMIENIOWE

Proces laminacji płomieniowej polega na połączeniu za pośrednictwem pianki poliuretanowej dwóch warstw materiałów tekstylnych, skayów, foli barierowych lub innych elastycznych komponentów.

Firma Kora Textiles oferuje materiały tekstylne laminowane płomieniowo oraz usługę laminowania płomieniowego. Produkty oferowane przez naszą firmę są produkowane na najnowocześniejszym dostępnym w Polsce oraz Europie parku maszynowym.

Ogromny ciąg laminowania płomieniowego wyposażony jest w niezbędne zapasy dla materiałów doklejanych z obu stron oraz pianki. Stosowanie zapasów w przypadku produkcji dużych partii materiałów pozwalają zmniejszyć ilość błędów technologicznych.

Ciąg laminujący jest wyposażony także w prostowarkę wzorów najnowszej generacji oraz system zadruku wewnętrznej strony powstałego laminatu w celu pełnej identyfikacji jakościowej produktu.

Czym jest laminacja?

Laminowanie polega na łączeniu różnych materiałów za pomocą maszyn do laminowania. Zachowuje indywidualne właściwości i cechy każdej warstwy. Materiały laminowane mają lepszą wytrzymałość, stabilność, trwałość, komfort i wygląd jako całość.

Laminowanie służy do łączenia materiałów, takich jak pianki, dzianiny, tkaniny, folie PCV, skóra, sztuczna skóra, włóknina, folia, papier, metal, plaster miodu lub inne materiały. Podczas procesu laminowania istotne są takie czynniki, jak ciepło maszyny, ciśnienie, czas oraz jakość kleju i materiału.

Najbardziej wszechstronni producenci zaawansowanych materiałów wytwarzają różnorodne rozwiązania w zakresie laminatów za pomocą szerokiej gamy procesów, takich jak ogrzewanie, ciśnienie, spawanie lub klejenie. My skupiamy się na bardzo wydajnej i efektywnej metodzie, jaką jest laminowanie płomieniowe.

Proces laminowania płomieniowego

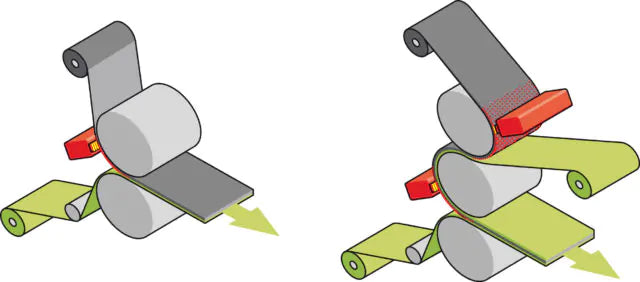

Laminowanie płomieniowe to proces laminowania materiałów elastycznych ciepłem wytwarzanym przez otwarty płomień. Ogólnie rzecz biorąc, warstwa materiału rdzenia (taka jak pianka poliuretanowa) będzie musiała być pod wpływem otwartego płomienia, aby mogła rozwinąć się kleistość, aby następnie przylgnąć do innej warstwy, takiej jak tkanina lub winyl.

W przypadku pianki i tkaniny zwinięte wyroby piankowe przepuszcza się przez otwarty płomień, a strona wystawiona na działanie ciepła topi się lekko i staje się lepka. Następnie jest natychmiast łączony z tkaniną i obie sklejają się bez potrzeby stosowania dodatkowych klejów.

Proces ten zapewnia dodatkową funkcjonalność i wszechstronność z tkaniną po jednej stronie i włókniną po drugiej, tkaniną po obu stronach oraz wieloma odmianami kombinacji tkanin, tworząc kompozyty, w tym pianki, folie i dzianiny.

Te połączone materiały kompozytowe będą miały właściwości i cechy, których poszczególne warstwy nie miałyby same z siebie. Warto się zastanowić, czy taka wszechstronność byłaby korzystna dla Państwa wymagań.

Korzyści z laminowania płomieniowego

- Wydajny proces: jest tańszym i bardziej wydajnym proesem niż inne alternatywy laminowania. Proces jest szybki i produktywny.

- Uniwersalność materiału: bardzo skuteczna metoda łączenia elastycznych pianek (najczęściej poliuretanowych) i niektórych włóknin z szeroką gamą innych podłoży, w tym tkanin, folii i papierów, o ile materiał rdzenia jest laminowany płomieniowo

- Brak wymogu klejenia: proces nie wymaga dodatkowych technologii klejenia, z szeroką możliwością łączenia materiałów w jednym kroku. Ten brak zmniejsza całkowity koszt

- Zrównoważony rozwój: brak kleju poprawia jego podatność na recykling i ponowne użycie, ponieważ jeden składnik wymaga oddzielenia mniej.

- Możliwość wielowarstwowości: masz wszechstronność kompozytów, tworząc laminat po jednej lub obu stronach materiału rdzenia.

- Zmienna grubość: kompozyty mogą mieć grubość nawet 1,9 cm, a niektóre zastosowania mogą nie zwiększać grubości, wykorzystując tylko bardzo cienką warstwę pianki poliuretanowej

Dzięki wszechstronności, szybkości i niższym kosztom laminowanie płomieniowe może być potężnym procesem kompozytowym.

Pianka PU jest najczęściej stosowana w laminowaniu płomieniowym ze względu na swoje unikalne właściwości (miękka, elastyczna itp.). Spajanie płomieni może zachować jego elastyczność i miękkość.

W przypadku zastosowań laminowanie płomieniowe jest szeroko stosowane w siedzeniach samochodowych, transporcie publicznym, obuwiu, tapicerce i innych zastosowaniach przemysłowych.

MATERIAŁY TE MAJĄ ZASTOSOWANIE W:

- Branży meblarskiej i tapicerstwie

- Branży medycznej

- Branży obuwniczej

- Branży motoryzacyjnej

- Branży wózków i fotelików dziecięcych

- W membranach

- W izolacjach

- Różnorakich wyrobach sportowych

Zapraszamy do kontaktu!

MASZ PYTANIA?

Masz pytania dotyczące oferowanych produktów? A może chcesz bliżej poznać proces technologiczny, według którego wytwarzane są poszczególne tkaniny i dzianiny? Nie czekaj i skontaktuj się z nami już dziś!

Zadzwoń do nas na (+48) 730 020 800 lub napisz na kora@koratextiles.com

Nasz zespół z chęcią udzieli Ci niezbędnych informacji i pomoże wybrać odpowiednie produkty i usługi.